What Are Biofilms?

The best way to protect against biofilms is prevent their formation.

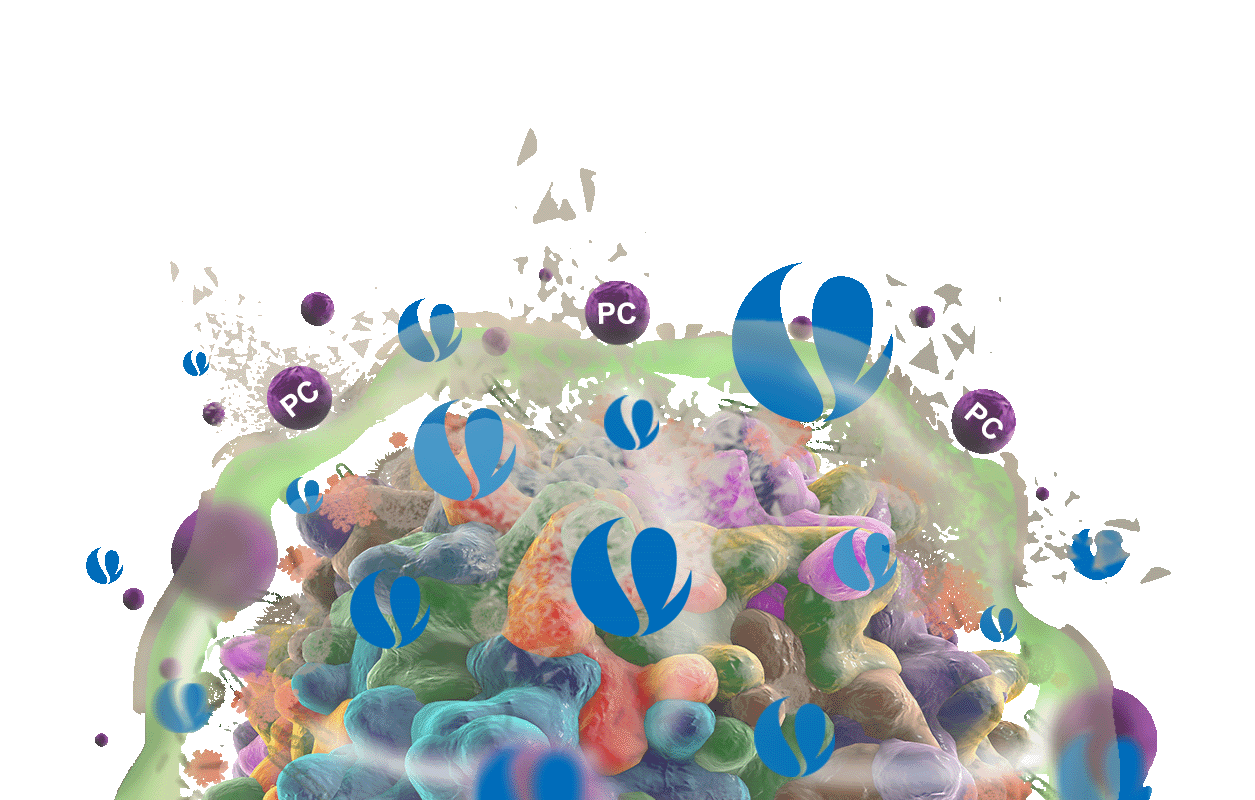

Biofilms are smart and resistant.

Biofilms protect microorganisms from disinfection and allows pathogens injured by environmental stress and disinfectants to recover and grow. It can require up to 1,000x the normal dose of a commercial sanitiser to remove a biofilm Bacteria can repopulate within a biofilm within 48 hours if not properly removed.

Why do Biofilms Matter

Failure to eliminate and remove biofilms can lead to significant human health and operational challenges. Biofilms, the natural habitat for microorganisms, impact daily life by harbouring dangerous pathogens, bacteria and viruses.

Biofilms also cause billons in economic damage through energy loss, equipment damage and product contamination — placing brands and consumers at risk for a foodborne disease outbreak.

The Sterilex Difference

Renowned for pioneering solutions that target and eliminate biofilm in complex environments, Sterilex has been a trusted leader in biofilm control across the United States for over two decades.

Approved in the UK

Sterilex TerraSence products offer proven efficacy against Listeria, Salmonella, E. coli, Staphyloccus, etc. using EN Test Methods.

Revoltionary Chemistry

Products featured in our TerraSense line showcase Sterilex's newest chemistries that are revolutionizing the hygiene space.

Continued Protection

If not managed well, biofilms can repopulate within 48 hours. Continued use of ProvaCharge, helps ensure a system is fully clean by destroying biofilms and simultaneously killing pathogens.

Reach Harbourage Niches

ProvaCharge foaming chemistry fills to reach all impossible-to-reach places.

Penetrate Biofilm Matrix

Combination chemistry penetrates and destroys biofilms to kill biofilm bacteria.

Kills biofilm bacteria

Kills up to 99.9999% of bacteria in biofilms

Related Resources for Biofilm

Operational Benefits of Biofilm control

Reduced recall risk

Protect food processing plant assets: both product and equipment

Reduced downtime and holds due to product contamination

Reduce labour needs by reducing scrubbing and recleaning

Reduce water needs by reducing recleaning

Extend shelf life by controlling spoilage organisms

Resources & Media

Explore our blog, white papers, case studies, and more for more in-depth information and insights.